FOR LASER / PLASMA CUTTING MACHINES

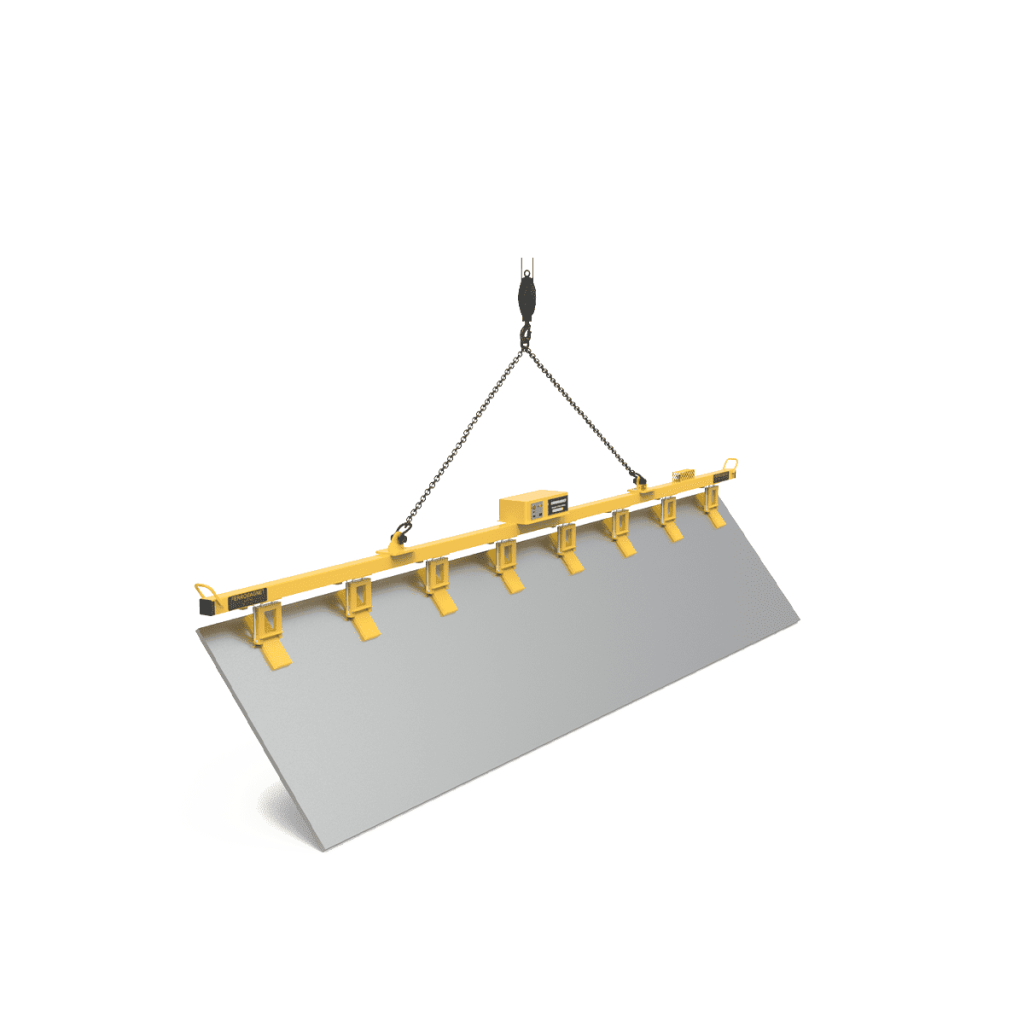

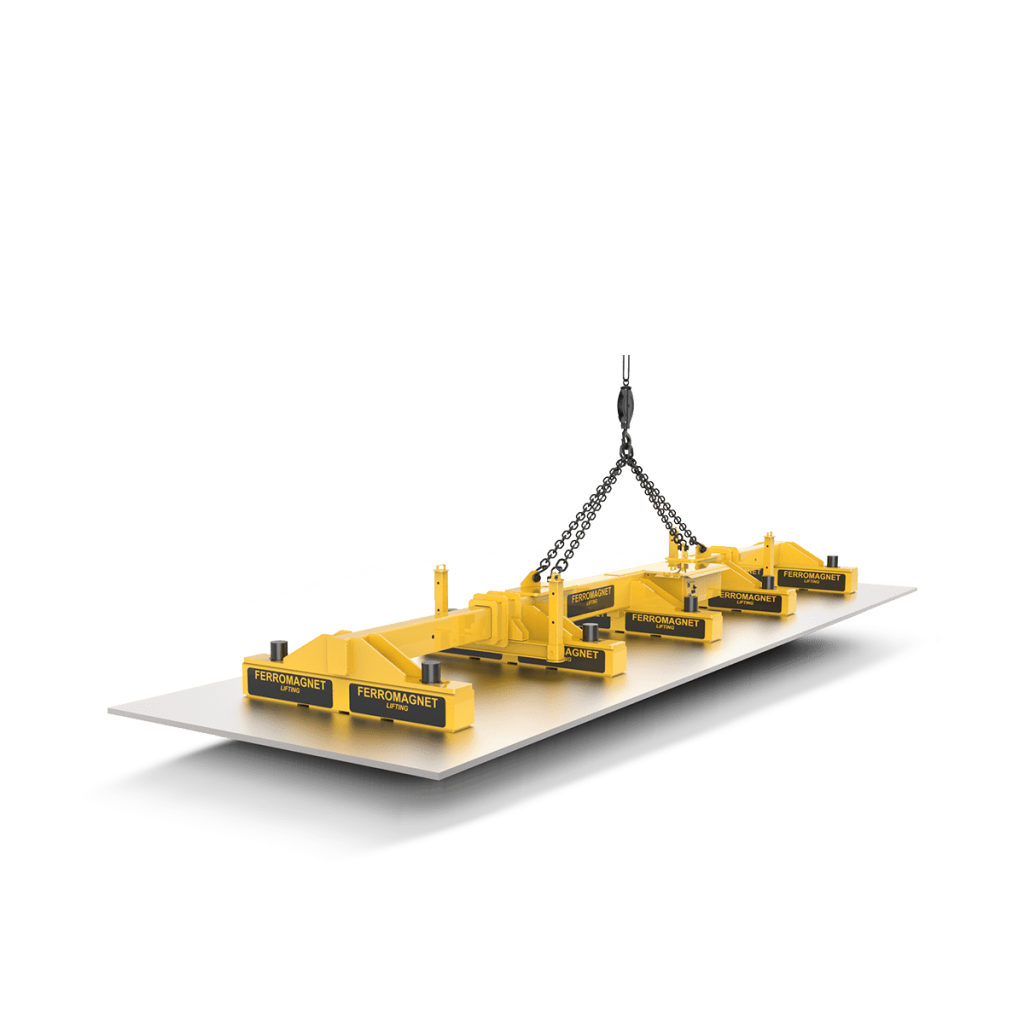

ELECTROMAGNETIC SHEET LIFTING SYSTEM

The system specially designed for laser/plasma cutting machines enables the placement of sheet metal plates onto the cutting machines and the removal of cut pieces after the cutting process, allowing for a continuous and efficient cutting operation.

It eliminates the risks and time loss that would arise from manually removing the cut pieces one by one or using conventional methods.

Its ability to be multifunctional distinguishes it from other lifting/handling systems.

The electromagnetic lifting systems for laser/plasma cutting machines, designed by professional engineers in the FERROMAGNET Design Department, provide operators with the ability to operate the system remotely using a user-friendly control unit.

ADVANTAGES OF ELECTROMAGNETIC SHEET LIFTING SYSTEMS FOR LASER CUTTING MACHINES

FERROMAGNET Electromagnetic Systems utilize the latest technological trends in the permanent electromagnetism industry and carry out its own R&D studies.

Unlike other traditional lifting and handling equipment, it easily transports iron/steel/metal parts without bending or damaging them.

Operators using FERROMAGNET Magnetic Sheet Plate Lifting Systems for Laser Plasma Cutting Machines do not need to use dangerous and primitive methods such as slings, ropes, or hooks, nor do they have to work under heavy loads, thanks to the use of remote control.

The electromagnetic systems that work with a single action are environmentally friendly, offering nearly 99% energy savings by requiring electricity only during the opening and closing process and do not require extra battery power.

FERROMAGNET Magnetic Systems are produced through detailed calculations and R&D studies based on the length and weight of the parts to be lifted/transported. As a result of these studies, even the heaviest parts can be transported safely and easily.

FERROMAGNET Magnetic Lifting Systems, which work with two simultaneous buttons to prevent accidents, are equipped with lights indicating the working status of the magnet, helping operators make more accurate movements.

Equipped with contact measurement sensor technology linked to the lifting mechanism, the system prevents accidents that could occur if the electromagnetism is turned off during the lifting/transporting of sheet, plate, iron, and steel materials.

FERROMAGNET Magnetic Sheet Plate / Iron Steel Lifting Systems for Laser Cutting Machines do not cause work-related accidents, unlike conventional lifting equipment.

Unlike its competitors, which have international safety standards of 2.8, FERROMAGNET's electromagnetic lifting and handling systems have a minimum safety standard of 4.

FERROMAGNET Electromagnetic Lifting Systems, which allow parts to be lifted without bending, can be opened with a single touch and operated via remote control, maximizing safety measures and preventing work-related accidents. As a result, they aim to maximize productivity in production lines.

Always prioritizing customer satisfaction, FERROMAGNET Electromagnetic Systems, being a local manufacturer, provides on-site installation and, if needed, on-site technical service to its solution partners.

TECHNICAL SPECIFICATIONS OF ELECTROMAGNETIC SHEET LIFTING SYSTEMS FOR LASER CUTTING MACHINES

- Requires electricity only when switching to OPEN and CLOSED positions.

- Utilizes the latest technological trends in the permanent electromagnetism industry.

- Provides nearly 99% energy savings.

- Ensures fast loading, unloading, and cutting operations.

- Technical and repair support is provided from Turkey.

+90 530 088 90 16

You can contact us for all your magnetic system needs.

info@ferromagnet.biz

Ferromegnet Electromagnetic Systems is always ready to listen to your comments and suggestions.

Price Offer

Just fill out the form completely so that we can get back to you quickly.

REQUEST A QUOTE

We are sharing our contact information with you to address all requests and expectations regarding electromagnetic gripping and lifting systems as quickly as possible.

We know that the door to new partnerships is often opened through references, which is why our customers’ satisfaction is the best reference for our company. We would be happy to serve you and have you among us.

Get a price quote now to enhance the efficiency of your production line!

Don’t forget to follow our Linkedin, Instagram, Facebook, and YouTube accounts to stay updated on all the innovations in electromagnetic sheet lifting systems!

- Fill out our contact form to receive a quote for your company! Once you submit the form, our sales engineers will share the best product and price options for the electromagnetic gripping and lifting system you need.

- Approved quotes for electromagnetic gripping and lifting systems are communicated to our design team, detailing the industry, dimensions of the lifted parts, customer requirements, and technical specifications.

- The technical drawings meticulously prepared by our design team are shared with the customer in detail. Once the design is approved by the customer, the necessary preparations are completed, and it is forwarded to our production facility.

- Your electromagnetic systems are carefully handled at every stage in our production facility and receive full approval from our quality control unit before being delivered to your chosen warehouse or shipping service.