ARM MAGNETIC LIFTER: FUNCTIONS AND ADVANTAGES

Arm Magnetic Lifters are essential equipment for small-scale industrial enterprises. These lifters attach to systems such as cranes to lift heavy metal materials during the lifting and material handling processes, providing great convenience to small businesses. Using magnetic force to lift heavy loads, this steel lifting equipment offers many advantages. In this article, we will discuss in detail the functions, advantages, and industrial applications of arm magnetic lifters in small businesses.

1. WHAT IS AN ARM MAGNETIC LIFTER?

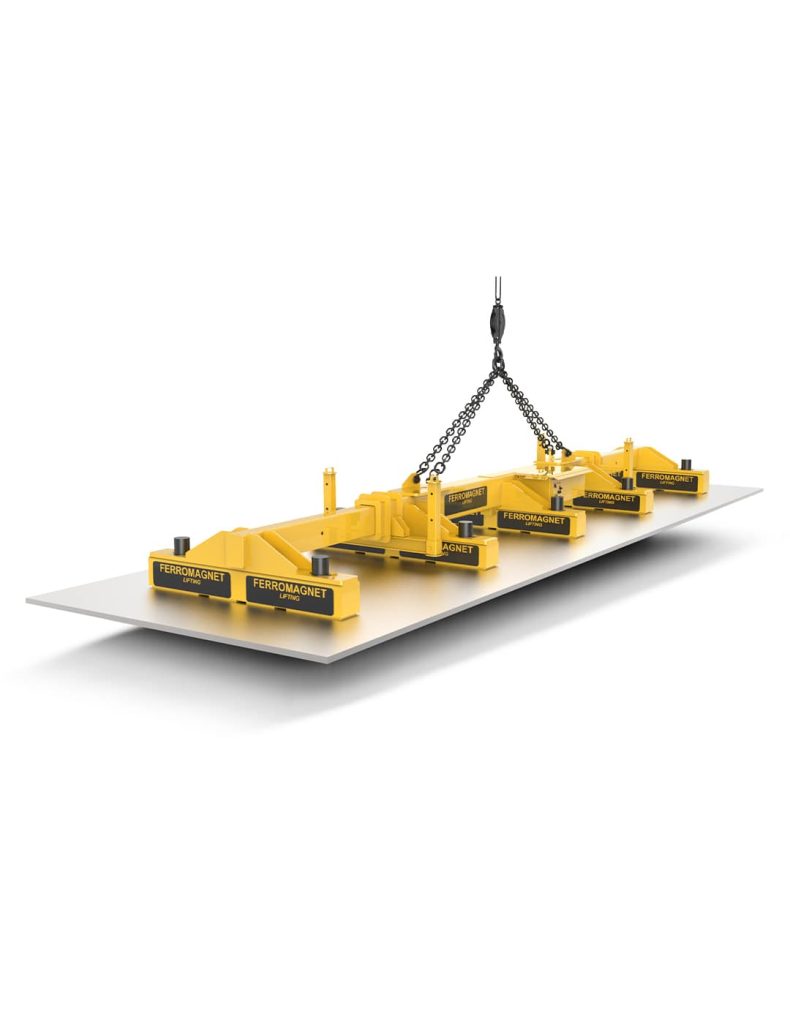

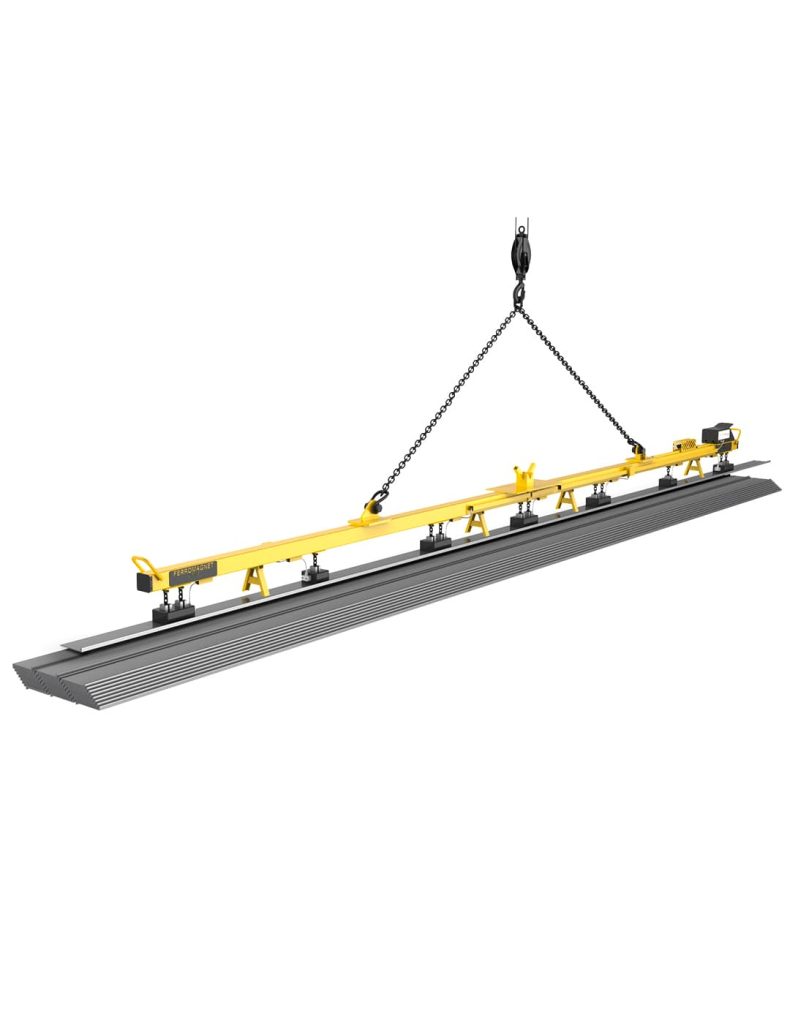

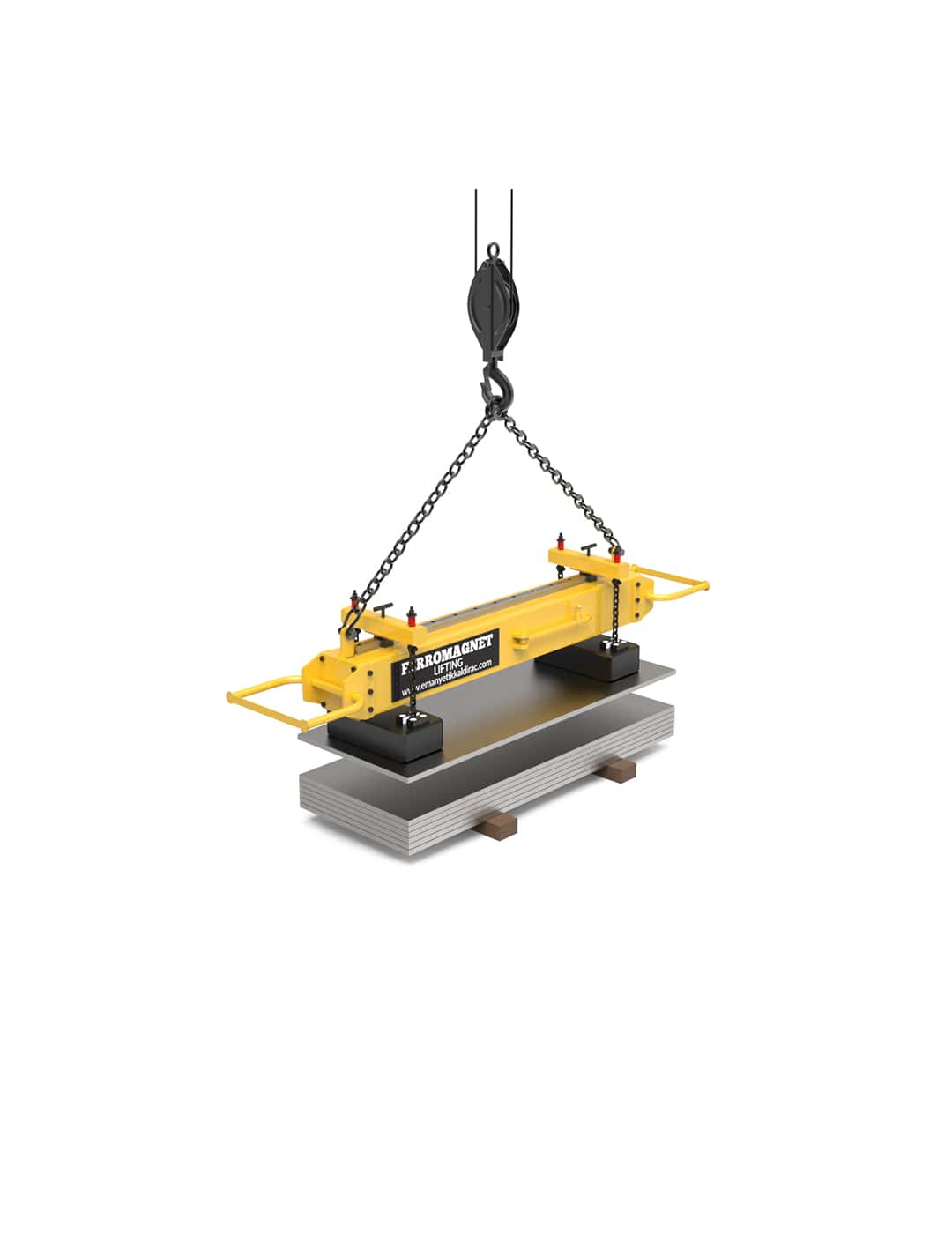

Arm Magnetic Lifters are lifting equipment that can lift heavy iron/steel loads using magnetic force. The magnetic force is generated through a coil that creates a magnetic field. This coil activates the magnet, allowing the lifter to lift the load. Arm magnetic lifters can safely transport loads thanks to their high-powered magnets.

2. FUNCTIONS OF ARM MAGNETIC LIFTERS

a. Load Lifting

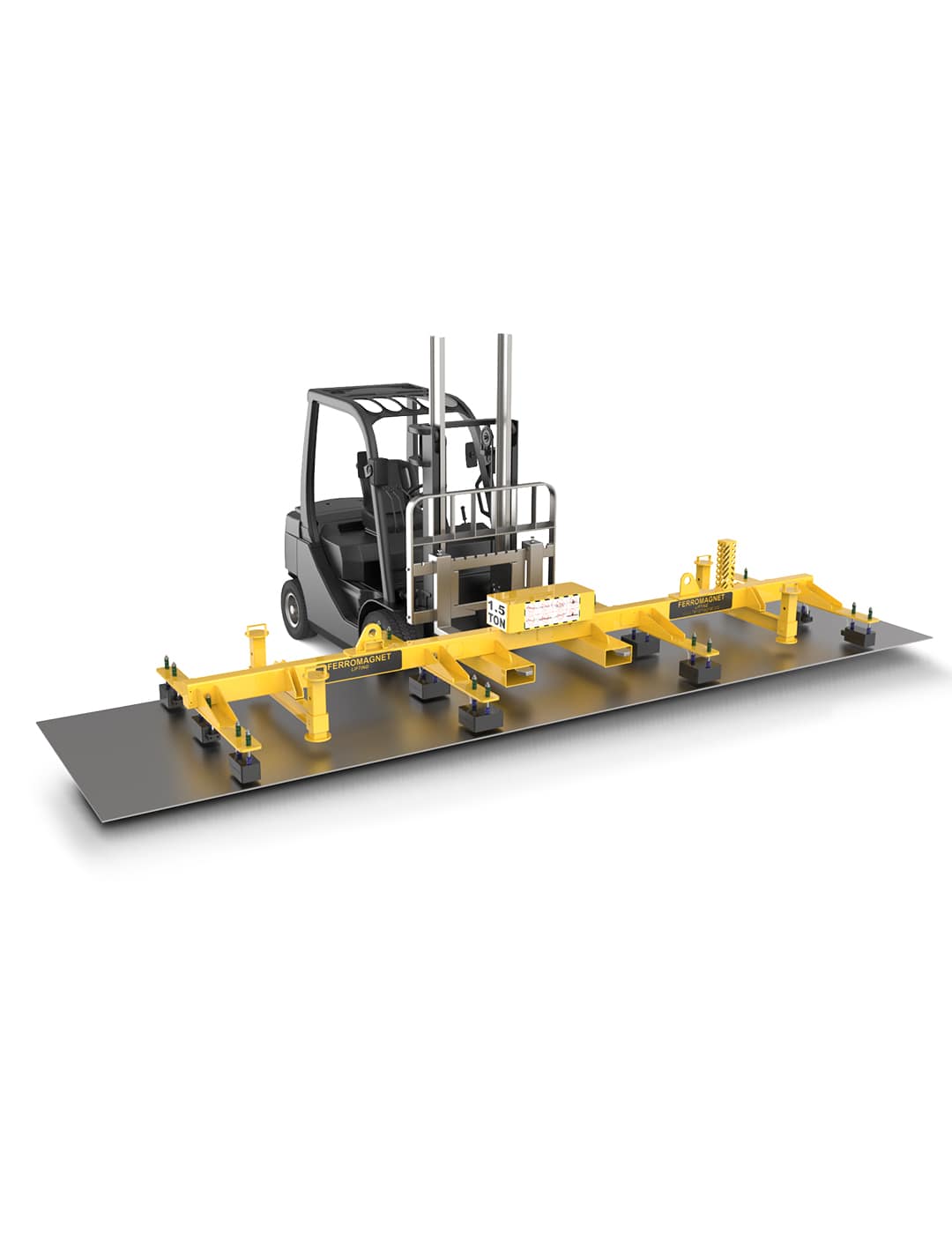

Arm magnetic lifters are known for their ability to easily lift heavy loads. They are frequently used in small-scale industrial facilities and have the capacity to lift loads of various sizes.

b. Precise Control

During magnetic lifting, arm magnetic lifters provide precise control without damaging the material. Users can lift and transport loads with high precision, which is a significant advantage in material handling. Some materials may require delicate handling, and arm magnetic lifters offer the precise control needed for these tasks, optimizing production processes.

c. Safe Lifting

The powerful magnets used in arm magnetic lifters ensure safe lifting by preventing unwanted drops or movements of the load. This is a major advantage for workplace safety. By using arm magnetic lifters, businesses can prevent accidents at the workplace and ensure the safety of their workers.

3. ADVANTAGES OF ARM MAGNETIC LIFTERS

Efficiency

Arm magnetic lifters use magnetic force as a lifting system. Thanks to the magnetic field generated by a coil, loads can be easily lifted by rotating the arm into position with a single movement.

Flexibility

Arm magnetic lifters have a flexible design that can adapt to various load sizes. Different weight and size options are available for arm lifters, but for heavy iron/steel sheets or plates, innovative and safer electromagnetic lifting systems should be preferred instead of arm lifters.

Ease of Maintenance

Magnetic lifters are made from durable materials and require minimal maintenance, such as simple dusting.

4. INDUSTRIAL APPLICATIONS OF ARM MAGNETIC LIFTERS

Arm magnetic lifters are a necessity for small-scale industrial businesses. They simplify load lifting operations, provide precise control, and create a safe environment. The advantages of efficiency, flexibility, and ease of maintenance are key factors that make arm magnetic lifters a preferred choice for small businesses. Therefore, it is recommended that small and medium-sized enterprises use arm magnetic lifters.

Technical Specifications

Size and Dimensions

The size of arm magnetic lifters varies depending on the intended use and application. The dimensions should be selected based on the size and weight of the material to be lifted.No Electrical Power Required

These lifters operate without the need for electricity, making them more energy-efficient and suitable for various environments.Compact Design

Arm magnetic lifters have a compact design with a small footprint, which allows them to be used in confined spaces without taking up much room.Ability to Lift Both Round and Flat Materials

These lifters can handle both round and flat materials, providing versatility for different types of loads.No Damage to Workpiece Surface

The magnetic lifter ensures that the surface of the workpiece is not damaged during lifting, offering a safe and gentle material handling solution.Low Maintenance

Arm magnetic lifters require little to no maintenance, which results in cost savings over time. They have no additional operating costs or complex maintenance requirements.

How to Use Magnetic Lifters?

Arm magnetic lifters, with their permanent magnetic design, do not require electrical power. The magnetic force is activated using the arm on the lifter. The device remains inactive unless the arm is rotated.

Clean the Surface of the Workpiece:

Before lifting, ensure that the surface of the workpiece is clean and free from dirt, oil, or debris to ensure a secure magnetic grip.Position the Lifter at the Center of Gravity:

Place the arm magnetic lifter over the workpiece at its center of gravity for optimal load distribution.Activate the Device:

Bring the lifter to the workpiece and ensure it is positioned correctly before activating the magnet.Activate the Magnet by Rotating the Arm:

Rotate the arm to activate the magnetic force, securing the workpiece with the lifter.Transport the Load Using a Crane or Other System:

Once the magnetic lifter has securely gripped the workpiece, use a crane or similar system to transport the material to the desired location.Place the Workpiece and Deactivate the Lifter:

Once the workpiece is in the desired position, place it down and rotate the arm back to its original position to deactivate the magnetic lifter.

CONTACT INFORMATION

Customer satisfaction is always our top priority. To address your requests and expectations as quickly as possible, we share this area with you. If you prefer, you can reach us faster at our hotline +905300889016.

+90 530 088 90 16

You can contact us for all your magnetic system needs.

info@ferromagnet.biz

Ferromagnet Electromagnetic Systems is always ready to listen to your thoughts and suggestions.

Price Quote

To ensure a quick response, simply fill out the form completely.

FERROMAGNET ELECTROMAGNETIC SYSTEMS is always ready to listen to your thoughts and suggestions!

To ensure a faster response, simply fill out the form completely…